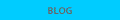

Less Than Two Square Feet of Floor Space POP Point of Purchase displays require a sense of dimension beyond advertising’s basic elements – software, fonts, and art – and an understanding of the characteristics of common, everyday cardboard as well.

|

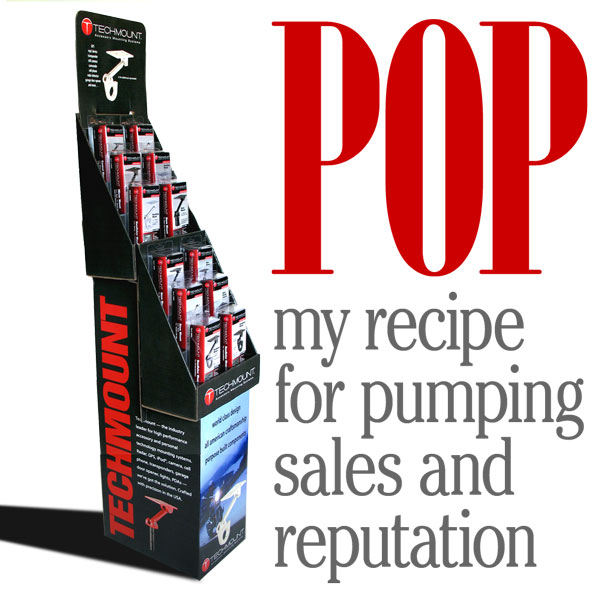

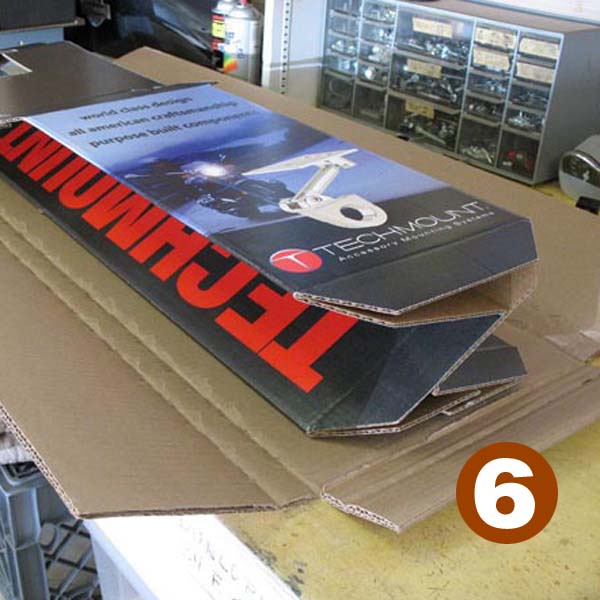

Creating a POP floor display begins with a prototype. Main considerations at this stage are the kind of printing – flexo or offset – and the type of cardboard. Shown is a mockup for the product shipper that will also serve as the counter display (6 units) and the floor display (2 x 6 units.) |

|

This project used white kraft for short run digital four-color. Long run alternatives are a 4c glued wrapper or traditional spot color rubber blanket printing. This prototype needed a base revision for better lateral stability. |

|

The original prototype next to a finished unit. In between were numerous modifications to adjust folds, tabs, slots and other critical dimensions. In the end maximum impact was obtained from a design taking up less than two square feet of floor space. |

|

There’s no getting around the fact that the more complex the display, the more labor that’s required for setup. Each unit is shipped with easy to follow fully illustrated setup instructions. |

|

The tab shown doesn’t seem like much but it ensures that the shipper’s secured to the base display – an unseen detail that separates quality design from just another fold-up box. |

|

Finished display neatly folded and ready to ship. The complete creative process includes making sure a shipping carton is designed to deliver the kit undamaged and ready to assemble. |

|

POP design is for professionals. Trying to reverse engineer for cheap offshore production usually doesn’t work. This manufacturer copied Siebenthaler Creative’s unique custom design but didn’t know that each project requires a fresh sheet of paper. Flaws included product packaging that didn’t fit, sloppy construction, and a lack of aesthetics. |